The WaveEL™ Concept

The WaveEL™ concept is based on three simple but important features – survivability, serviceability, and profitability.

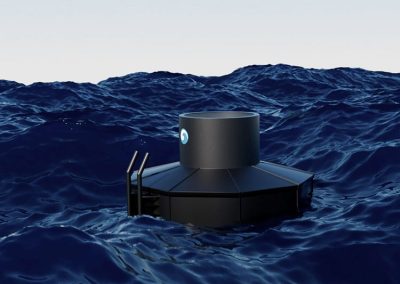

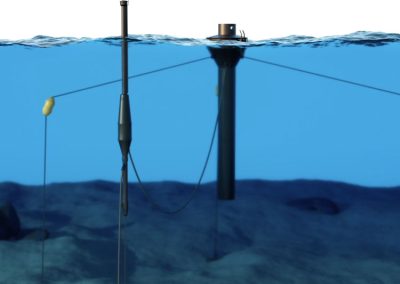

Survivability. Anyone familiar with the harsh, ocean environment knows that survival is hard but is an obvious necessity for a successful operation. The trick to survive is riding the waves, not fighting them. By building small buoys in relation to the length of the waves in which they work, you ensure the odds of survival are on your side.

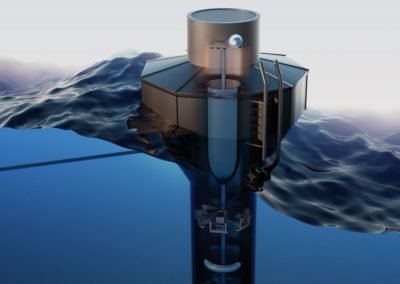

Serviceability require accessibility. With all serviceable components above water and with ease to board the buoy from small boats or large vessels alike, service can be performed safely, efficiently and without the need of divers. All connections on the WaveEL™ buoy as well as the WaveEL™ Hub are dry with no need for expensive “Wet Mate” connections.

Profitability, the third key feature for future success of the WaveEL™ system hinges on four easily defined – but not as easily obtained – parameters that determine the cost of the power produced. They are the manufacturing cost, the cost of launch and retrieval, the maintenance cost during the life of the device, and finally the system efficiency or output.

The cost of building a wave power device is much dependent on the amount of raw material needed. For this reason, the parameter kWh produced per unit of weight, have lately become a key factor in comparing different systems. The WaveEL™ buoy is different by having one of the highest outputs per unit of weight [kWh/year/kg] known in the industry.

Waves4Power has showed the feasibility of using smaller devices. Ease of handling during deployment as well as Wave4Power’s unique logistics approach from start to finish ensures that these, “small” units are perfectly suited for mass production and deployment.

Cost of operation and maintenance during the 25-year lifetime of the device, must be considered in the final cost calculations. Waves4Power’s focus on survivability, serviceability, modular design, and use of well-tested, standard components make for minimized operation and maintenance costs and for a profitable operation.